Learn about emotional learning (SEL) through outdoor activities and find out how your school can benefit from all-weather outdoor learning with the help of a canopy.

Read more

Discover the reasons why you should consider a term time canopy installation, from comprehensive planning to DBS-checked installers.

Read more

Explore the best material for school canopies, from steel to aluminium. Make an informed decision when enhancing your school’s space.

Read more

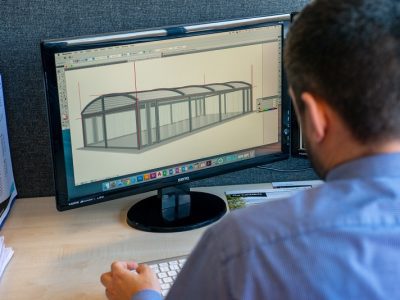

Find out how we pair industry-leading canopy design and manufacture with the best materials to achieve a functional and high-quality finish.

Read more

Find out how to protect students, staff and visitors in the winter months with these school safety tips for cold weather.

Read more

Make the most of your playground in every season and get ideas for winter outdoor play for early years and primary age kids.

Read more

Discover the impact of a school canopy with a closer look at a recent project and a Q&A with the School Business Manager at Allestree Woodlands School.

Read more

Find out more about our work with modular home builders and the importance of maintaining a reliable supply chain in modular house building.

Read more

Learn more about site-specific calculations and find out how a tailored solution from Canopies UK enhances safety and results in a higher-quality end product.

Read more

Make the most of your outdoor space no matter the season. Here are some great ideas for spring and summer outdoor learning and play.

Read more

Take a look at some of the ways you can apply for grants and raise funds for school improvements in 2023.

Read more

Find out the simple steps schools can take to make sure children stay protected from UV rays in the summer months.

Read more